-

-

-

PCB Production Main Materials

PCB Machine Spares

FPC Production Materials

-

-

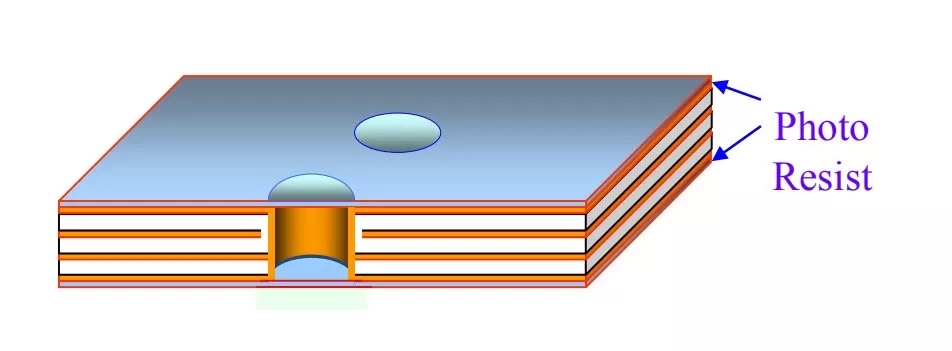

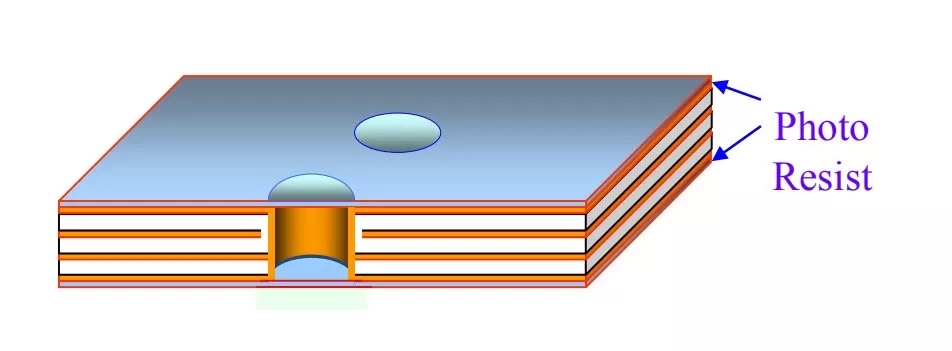

PCB DRY FILM PHOTORESIST FIRST FT-2538

PCB Production Main Materials

- Name: FIRST Dry Film for PCB

- Model: FT-2538

- Thickness: 38±1μm

- Width: 200-600mm

- Length: 180m/roll (2 rolls/box)

-

左对齐居中右对齐

-

- FIRST Dry Film

Features:

(1)Excellent tenting performance could contribute to higher yield;

(2)Excellent resolution and adhesion;

(3)Less scum occurrence and foam could improve the service life of equipment;

(4)Excellent stripping property could enhance output performance;

Notice on Storage:

(1)Keep the dry film in a dark, cool place with relative humidity of less than 60 %, while the temperature is 5-20 oC. And the shelf life of the film stored in this way is 6 months.

(2)Lay down film rolls horizontally by using racks for storage. If they are laid vertically, sheets of dry film may slip one by one.

(3)Following the first-in first-out (FIFO) rule to use the stored product.

Notice on Safety:

As the dry film contains acrylic monomers, it may cause skin irritation and allergy. Therefore it requires a normative operation and good protection.

(1)Put on protective gloves to avoid contacting dry film directly. Flush with hand washing and water when you contact it. While it contacts your eyes, flush with enough water and see a doctor.

(2)The lamination temperature should be controlled in the recommended range to reduce the volatile gas. And install a device for exhausting gas on laminator.

(3)In the process of using dry film, the polyethylene film and polyester film should not be reused.

(4)Wear protective tools such as glasses and gloves while you do a maintenance check of the machines or while you renew developer, etcher and stripper.

Notices in application:

(1)Take out dry film rolls from black sheets under a yellow lamp, but do not leave them for a long time.

(2)The color of the film is bluish green. Though the color may gradually fade with time, it should not influence the performances.

(3)Substrate preheating at too high temperature for a long time may cause rust. It should be done for less than 2 minutes at 150 oC and the substrate surface temperature prior to lamination should be less than 75 oC.

SHIPPING

——————————————————————— More Details ———————————————————————

Please kindly feel free to contact us:

sales5@sz-kewei.com

0086-13537348123

All copyright © Shenzhen Kewei Industries Limited