-

-

-

PCB Production Main Materials

PCB Machine Spares

FPC Production Materials

-

-

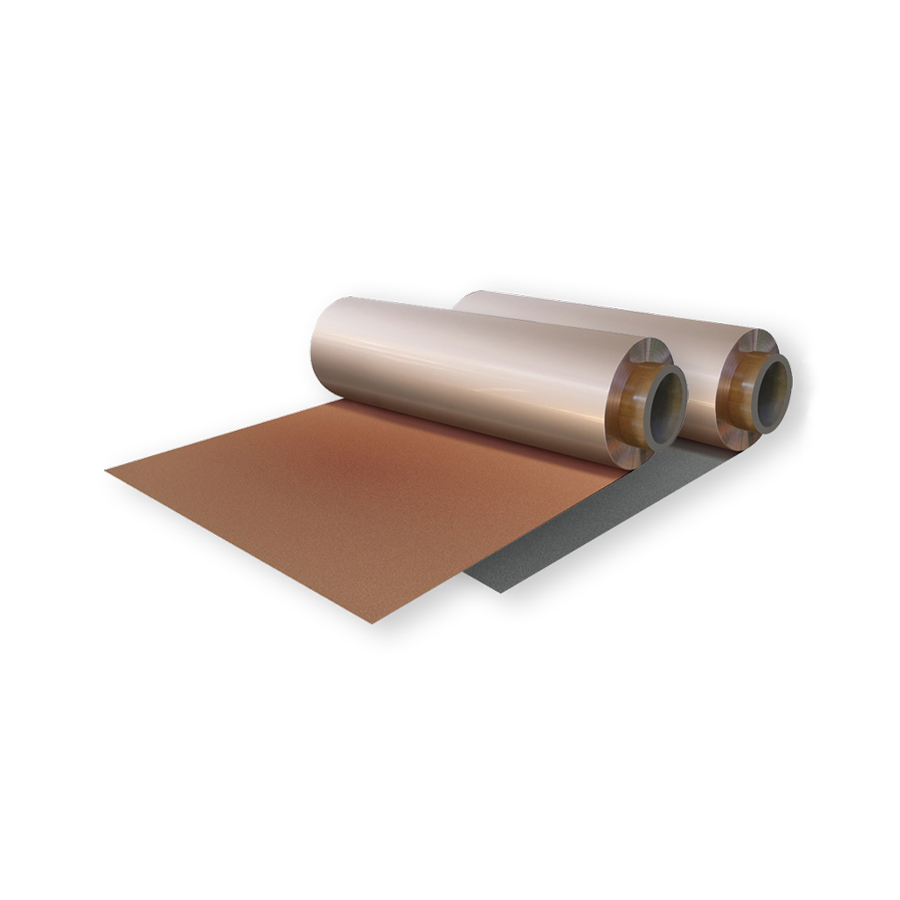

FCCL Flexible Copper Clad Laminate for FPC Production

Flexible copper clad laminates are widely used in aerospace equipment, navigation equipment, aircraft instruments, military guidance systems and electronic products such as mobile

PCB Production Main Materials

ED and RA Copper on FCCL

The copper foils can be ED (Electro Deposit) Copper or RA (Rolled & Annealed) Copper. The standard ED copper typically has a relatively high profile or rough surface as compared to rolled annealed copper. ED copper tends to lack flexibility and does not promote good signal integrity. RA copper has been used extensively in the flex industry for decades. In complex and multilayer flexible and rigid-flex PCB designs, MADPCB recommends FCCL with RA copper foil.

Single/double-sided black matte side foil--ED FCCL

|

Model |

Thickness required size |

||||

|

ED(Cu) |

Polyimide film(PI) |

Ad glue |

Single Side |

Double Side |

|

|

HABEK030513S |

12µm |

12.5µm |

13µm |

37.5µm±2 |

|

|

HABEK030513D |

12µm |

12.5µm |

13µm |

|

62.5µm±2 |

|

HABEK031013S |

12µm |

25µm |

13µm |

50µm±2 |

|

|

HABEK031013D |

12µm |

25µm |

13µm |

|

75µm±2 |

|

HABEK050513S |

18µm |

12.5µm |

13µm |

43.5µm±2 |

|

|

HABEK050513D |

18µm |

12.5µm |

13µm |

|

74.5µm±2 |

|

HABEK030518S |

12µm |

12.5µm |

18µm |

42.5µm±2 |

|

|

HABEK030518D |

12µm |

12.5µm |

18µm |

|

72.5µm±2 |

|

HABEK051013S |

18µm |

25µm |

13µm |

56µm±2 |

|

|

HABEK051013D |

18µm |

25µm |

13µm |

|

87µm±2 |

|

HABEK101020S |

35µm |

25µm |

20µm |

80µm±2 |

|

|

HABEK101020D |

35µm |

25µm |

20µm |

|

135µm±2 |

Single/double sided-Red matte side foil--ED FCCL

|

Model |

Thickness required size |

||||

|

ED(Cu) |

Polyimide film(PI) |

Ad glue |

Single Side |

Double Side |

|

|

HAREK030513S |

12µm |

12.5µm |

13µm |

37.5µm±2 |

|

|

HAREK030513D |

12µm |

12.5µm |

13µm |

|

62.5µm±2 |

|

HAREK031013S |

12µm |

25µm |

13µm |

50µm±2 |

|

|

HAREK031013D |

12µm |

25µm |

13µm |

|

75µm±2 |

|

HAREK050513S |

18µm |

12.5µm |

13µm |

43.5µm±2 |

|

|

HAREK050513D |

18µm |

12.5µm |

13µm |

|

74.5µm±2 |

|

HAREK030518S |

12µm |

12.5µm |

18µm |

42.5µm±2 |

|

|

HAREK030518D |

12µm |

12.5µm |

18µm |

|

72.5µm±2 |

|

HAREK051013S |

18µm |

25µm |

13µm |

56µm±2 |

|

|

HAREK051013D |

18µm |

25µm |

13µm |

|

87µm±2 |

|

HAREK101020S |

35µm |

25µm |

20µm |

80µm±2 |

|

|

HAREK101020D |

35µm |

25µm |

20µm |

|

135µm±2 |

RA FCCL

|

Model |

Thickness required size |

||||

|

RA(Cu) |

Polyimide film(PI) |

Ad glue |

Single Side |

Double Side |

|

|

HARGK050514S |

18µm |

12.5µm |

14µm |

44.5µm±2 |

|

|

HARGK050513D |

18µm |

12.5µm |

13µm |

43.5µm±2 |

74.5µm±2 |

|

HARGK051014S |

18µm |

25µm |

14µm |

57µm±2 |

|

|

HARGK051013D |

18µm |

25µm |

13µm |

56µm±2 |

87µm±2 |

|

HARGK101020S |

35µm |

25µm |

20µm |

80µm±2 |

|

|

HARGK101020D |

35µm |

25µm |

20µm |

80µm±2 |

135µm±2 |

Technical Parameter

|

Characteristic |

Test Condition |

ZT-051313SD |

Test Standard |

Test Mothod |

|

|

Peel Strength(kgf/cm2) |

T |

0.96 |

≥0.7 |

IPC-TM-650 2.4.9 |

|

|

Chemical Resistance |

5%HCI/10min |

0.92 |

4.1% |

droop rate ≤20% |

IPC-TM650 2.4.9 |

|

5%NaOH/10min |

0.89 |

5.2% |

|||

|

UPA/10min |

0.94 |

2.1% |

|||

|

Method B(%) |

MD |

Let stand for 10min |

0.043 |

≤+0.15% |

IPC-TM-650 2.2.4 |

|

TD |

Let stand for 10min |

-0.028 |

|||

|

Method C(%) |

MD |

150℃/30min |

0.057 |

||

|

TD |

150℃/30min |

-0.32 |

|||

|

MIT(times) |

MD |

500g/0.8R |

860 |

≥800 |

JIS C-6471 |

|

TD |

858 |

||||

|

Thermal Resistance |

300℃/10S |

OK |

No delamination, bubbles |

IPC-TM-650 2.4.13 |

|

|

Dielectric Constant(DK) |

C-24/23/50 |

3.1 |

4.0 |

IPC-TM-650 2.5.5.3 |

|

|

Dissipation Factor(DF) |

0.028 |

0.04 |

|||

|

Surface Resistance |

C-95/35/90 |

2.3*1014 |

1013 |

IPC-TM-650 2.5.17 |

|

|

Volume Resistance |

1.6*1016 |

1015 |

|||

|

Water Absorption |

A |

1.23 |

≤2.0 |

IPC-TM-650 2.6.2 |

|

Package

|

Package |

Meter |

roll core |

|

|

Single-side panel |

200 |

3 inch |

|

|

Double-side panel |

1/2OZ |

100 |

6 inch |

|

1OZ |

50 |

6 inch |

|

1. The finished product must be vacuum packed to avoid oxidation of the copper surface; if the package has been opened, please put it back in the original package after use, and place it in a dry room temperature environment

2. The shelf life of the finished product is 12 months, please use it within the validity period

3. Avoid heavy pressure, spot injuries, throwing, etc. during transportation.

More details, please kindly contact:

sales5@sz-kewei.com

0086-13537348123

All copyright © Shenzhen Kewei Industries Limited